We live in an increasingly digital world that we enter via modern displays. And because these are used on a daily basis, discerning users intuitively recognize their quality. In order to guarantee this consistent, optimum quality, GMS tests its customers’ displays intensively in its own test laboratory – even before delivery.

Displays are manufactured in record time and have become high-performance hardware, and not just since the introduction of touchscreens. However, as with all technical components, production errors or transport damage can occur. Getting to the bottom of these faults requires a fully equipped test laboratory and a qualified team that knows what is important.

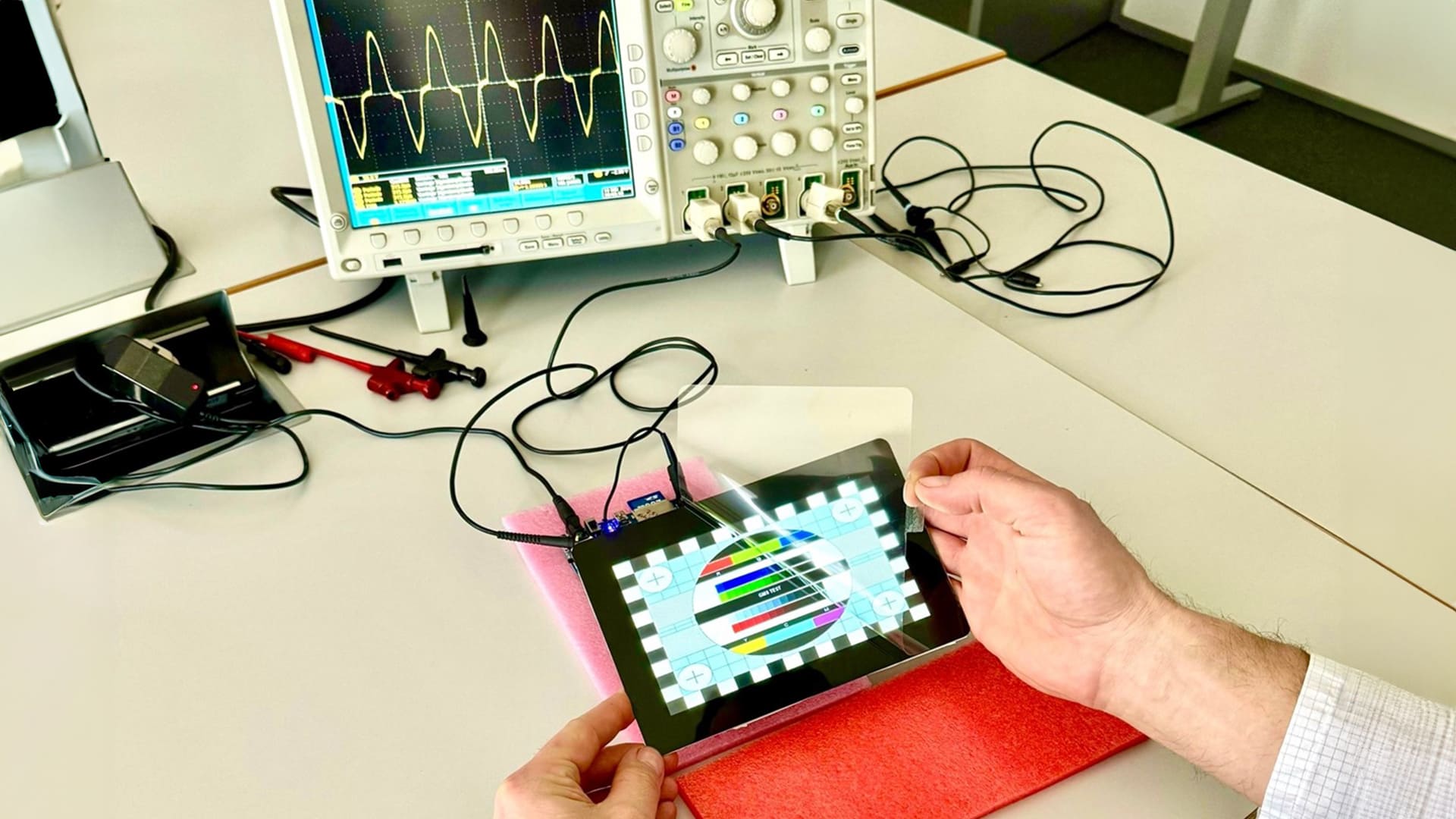

Fully-equipped test lab

“Our test lab is equipped with everything needed to ensure the quality and performance of a display. Here, our highly qualified employees use a variety of test devices, computers, control boards, customer applications and various measuring devices to track down errors. If necessary, we even subject the displays to stress tests in order to test their perfect functioning even under extreme conditions,” says GMS Managing Director Herbert Weiss.

Leave nothing to chance

Nothing is left to chance, from checking the dimensions according to the drawing and the electrical function to the visual impression and the correct pressure on the cover glass for touchscreens. Both random samples and complete batch tests are carried out to ensure that every single display meets GMS’s high standards.

GMS customers benefit from this comprehensive quality assurance, which ensures that every display delivered works reliably and performs well. By identifying problems at an early stage, potential defects can be rectified before delivery.

“Quality and reliability are crucial for our demanding customers. They must be able to rely on us and our products. Our test laboratory is an important component in meeting this requirement,” says Herbert Weiss.