Anyone looking for individual display and touch solutions for special applications in the medical, automotive or consumer sectors usually quickly reaches their limits. Even if a suitable display is quickly found, a suitable frame or housing is usually still needed to accommodate this display. But what do you need to look out for? Do the housing, display and cover glass/touch really fit together? How large can the tolerances be? And once the optimum combination has been found, who will install it professionally?

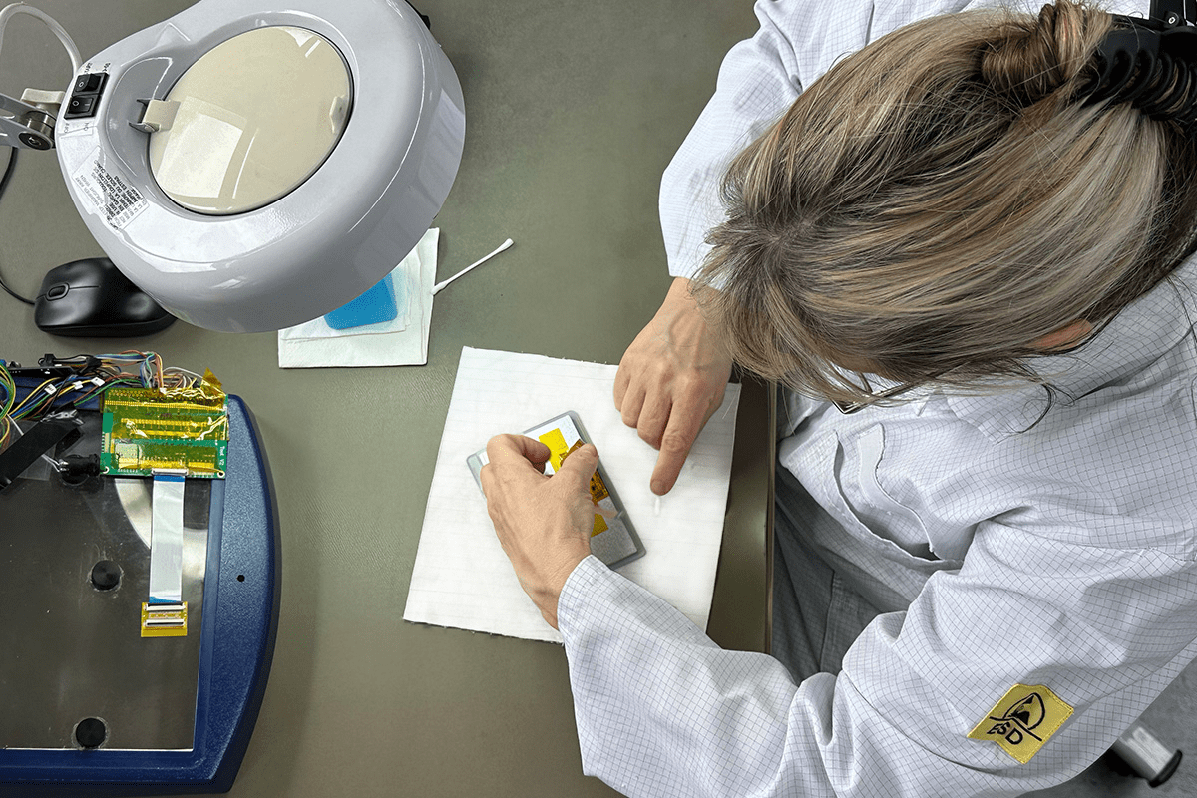

The display pioneer GMS can help. It has its own in-house production facility with qualified employees who specialize in the precise final assembly of displays and housings. This is a specialized assembly line that offers customers considerable advantages.

Close cooperation for perfect products

To take the pressure off its customers, GMS supports them throughout the entire process – from design-in support to delivery. Close cooperation is crucial here. “In the first step, our customers order the required displays from us and the desired enclosures directly from their preferred suppliers. We then support them with our many years of expertise in the design-in and construction of the housings so that the displays are perfectly integrated, function in the long term and are easy to read,” explains Herbert Weiss, Managing Director at GMS.

GMS takes over organization

“We then take over the entire organization,” says Herbert Weiss. For example, GMS first checks with the customer whether the tolerances and flatness of the housing meet the requirements of the selected displays. When the selected products are delivered to Villingen-Schwenningen, GMS checks and cleans them if necessary and prepares them for assembly.

“We then assemble each enclosure and display professionally, ensuring, for example, that they are pressed together evenly to the specified thickness. This ensures a permanent connection and prevents potential problems, such as the display detaching from the housing at a later date,” says the GMS Managing Director. In addition to the assembly of displays and housings, GMS also offers the assembly of complete display electronics modules.

Quality control for error-free function

Before the displays are delivered to customers, GMS carries out a quality check. Each unit undergoes an electronic and mechanical test to ensure that it functions perfectly and to guarantee the high quality and reliability of the end products.

Warranty provides security

“In addition to the points mentioned above, which we take care of for our customers, we also offer them peace of mind. They can rest assured that they will receive a professionally installed product. And they can also rely on the statutory warranty claims,” says Herbert Weiss. Overall, GMS customers benefit from a smooth process, comprehensive know-how and support as well as first-class quality with GMS as their partner in display production.